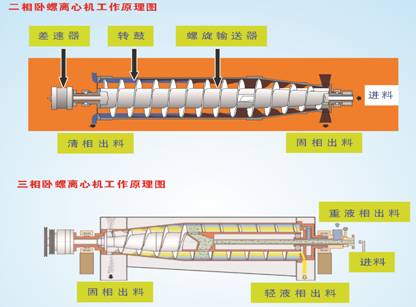

Basic principle of horizontalscroll discharge centrifuges (namely decanter centrifuges): the light liquid, heavy liquid and solid (dregs) in the mixed liquid (suspension) have

different densities and are immiscible, and any two or three phases therein are then

under different centrifugal forces in the centrifugal force field, resulting in different

settling velocities, then achieving thepurpose of separation, layering or settling the

solid-phase particles in the liquid.

After entering into the high-speed turning drum,the solid-phase particles in the

mixed liquid run and settle on the drum wallunder the action of greatest centrifugal

force; the light liquid settles at the innermost place of the drum under minimum centrifugal force; and the heavy liquid settles in the middle (this phase exists in case of three-phase separation or does not exists in case of two phases); same as the drum’s turning direction, a screw feeder also turns at a high speed, and a constant speed difference is generated by the differential mechanism; the solid-phase particles settled on the drum wall are then fed by the screw feeder to the solid outletof the drum, and the light phase and heavy phase (this phase exists in case of three-phase separation or does not exists in case of two phases) are then separated out of different outlets. When used for two-phase separation, the machine is called two-phase decanter centrifuge (also called horizontal scroll centrifuge), and the machine used for three-phase separation is called three-phase decanter centrifuge. In our decanter centrifuges, the light liquid is exhausted by gravity force, and the heavy liquid is discharged by the centrifugal force