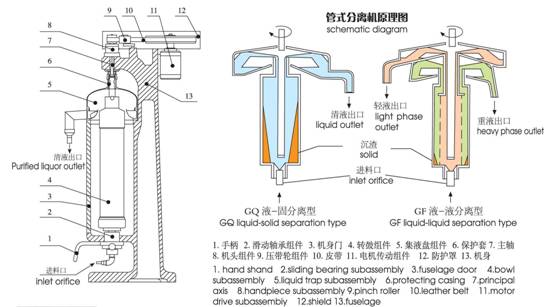

A centrifuge is composed of a main body, a transmission device, a bowl, a liquid trap and an inlet bearing block. A flexible principal axis is located at the upper part of the bowl and a damping floating bearing is designed at the lower part; the principal axis is connected to the driven wheel by a buffer seat, and power is transferred to the driven wheel by motor via a belt conveyor and tension pulleys to achieve the bowl rotating at extremely high speed around its own axis, forming a mighty centrifugal field; the feed liquid is injected via the inlet orifice at the bottom, and the centrifugal force drives the liquid to flow up along the bowl inner wall; liquid components stratify due to their different densities: the component with high density (solid) settles to the bowl inner wall, and the heavy liquid settles to the inside of the solid phase, flows out via the heavy liquid outlet and is collected by the heavy liquid trap; the light liquid in the components settles to the innermost part, flows out via the light liquid outlet and is collected by the light liquid trap; the solid phase, after depositing a period of time, can be extracted at shutdown. If the separation involves only a liquid and a solid, then separating heavy and light liquids is not needed. The liquid-solid types are called GQ types, and the liquid-liquid-solid types are GF types.