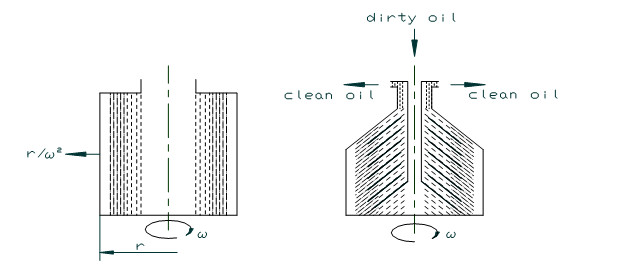

The indissoluble liquids and solids with different densities will be separated while they are rotated at a high speed in the bowl, where the particles with heavier density move to the inside wall of bowl body, the lighter liquid toward the center of the bowl. Because the centrifugal force generated in the centrifuge fields in much larger than the gravity force, it takes only very short time for the centrifuge separation to achieve the same separation efficiency in the gravity fields. Especially when the gravity separation cannot be available, the best method is used with centrifuge separation.

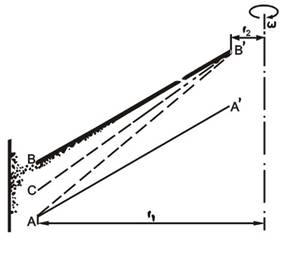

Separation space

There is a stack of discs installed in the bowl, which divide the bowl space into many conical cavities. That can shorten the sedimentation distance and improve the separation efficiency.

The moving trace of the limit particle “A” occurs between the discs (conical cavity).

Separation Methods

As per the requirements of application and the bowl functions, there are 3 methods, which are purification and clarification and concentration.

Basic principle of horizontalscroll discharge centrifuges (namely decanter centrifuges): the light liquid, heavy liquid and solid (dregs) in the mixed liquid (suspension) have

different densities and are immiscible, and any two or three phases therein are then

under different centrifugal forces in the centrifugal force field, resulting in different

settling velocities, then achieving thepurpose of separation, layering or settling the

solid-phase particles in the liquid.

After entering into the high-speed turning drum,the solid-phase particles in the

mixed liquid run and settle on the drum wallunder the action of greatest centrifugal

force; the light liquid settles at the innermost place of the drum under minimum centrifugal force; and the heavy liquid settles in the middle (this phase exists in case of three-phase separation or does not exists in case of two phases); same as the drum’s turning direction, a screw feeder also turns at a high speed, and a constant speed difference is generated by the differential mechanism; the solid-phase particles settled on the drum wall are then fed by the screw feeder to the solid outletof the drum, and the light phase and heavy phase (this phase exists in case of three-phase separation or does not exists in case of two phases) are then separated out of different outlets. When used for two-phase separation, the machine is called two-phase decanter centrifuge (also called horizontal scroll centrifuge), and the machine used for three-phase separation is called three-phase decanter centrifuge. In our decanter centrifuges, the light liquid is exhausted by gravity force, and the heavy liquid is discharged by the centrifugal force

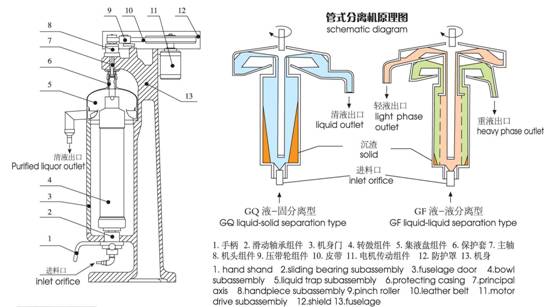

A centrifuge is composed of a main body, a transmission device, a bowl, a liquid trap and an inlet bearing block. A flexible principal axis is located at the upper part of the bowl and a damping floating bearing is designed at the lower part; the principal axis is connected to the driven wheel by a buffer seat, and power is transferred to the driven wheel by motor via a belt conveyor and tension pulleys to achieve the bowl rotating at extremely high speed around its own axis, forming a mighty centrifugal field; the feed liquid is injected via the inlet orifice at the bottom, and the centrifugal force drives the liquid to flow up along the bowl inner wall; liquid components stratify due to their different densities: the component with high density (solid) settles to the bowl inner wall, and the heavy liquid settles to the inside of the solid phase, flows out via the heavy liquid outlet and is collected by the heavy liquid trap; the light liquid in the components settles to the innermost part, flows out via the light liquid outlet and is collected by the light liquid trap; the solid phase, after depositing a period of time, can be extracted at shutdown. If the separation involves only a liquid and a solid, then separating heavy and light liquids is not needed. The liquid-solid types are called GQ types, and the liquid-liquid-solid types are GF types.