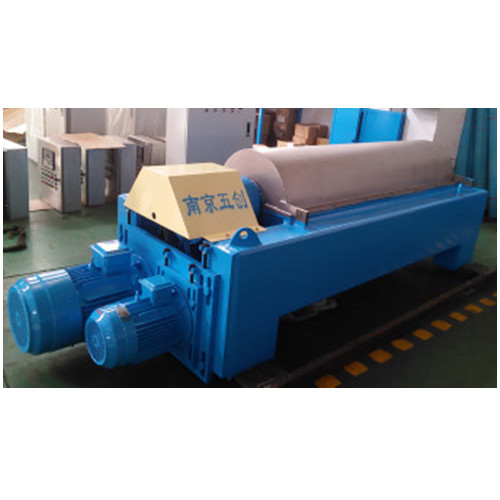

Principle of three-phase decanter centrifuges is as shown in the above figure. The substance to be separated is fed by the feeding tube into the accelerating

cavity of the spiral conveyor, then enters high-speed running drum wall. As the light liquid, heavy liquid and insoluble solid contained in the substance have different specific gravities, the three materials are subject to varied centrifugal forces: the insoluble solid settles into the inner wall (outside) due to its highest specific gravity and subject to maximum centrifugal force; the light liquid settles maximum far away from the inner wall (outside) due to its lowest specific gravity and subject to minimum centrifugal force; and heavy liquid settles in the middle place. The insoluble solid is discharged from the solid discharge port by a spiral feeder which has relative differential speed with the drum; and the light and heavy liquids are then separated by different structures inside the machine wherein the heavy liquid is discharged by the centripetal pump, and the light liquid is discharged via the force of gravity, thus the purpose of three-phase separation is achieved. In our three-phase decanter centrifuges, the light and heavy liquids are discharged via the force of gravity and the centrifugal force, which effectively prevents the phases mixture and incomplete separation. Ordinary three-phase decanter centrifuges often generate incomplete separation because of unstable light / heavy-phase liquid compositions, while in our centrifuges, the interface of light / heavy-phase liquids can be regulated with constantly changing material compositions in the machine working, thus optimal separation effect is achieved.

Currently, our three-phase decanter centrifuges are used in the separation of oils, water and slags / dregs in the coal tar industry, the petrochemical industry, the fish powder industry, the swill oil industry, the electrolytic copper industry, and the waste scraps in the slaughter houses.

Three-phase Decanter Centrifuges technical parameters

|

Type |

Bowl diameter(mm) |

Bowl length/ Bowl diameter |

Bowl speed (r/min) |

Main Power(Kw) |

|

LWS355 |

355 |

3.3-4.5 |

4000 |

15-18.5 |

|

LWS420 |

420 |

4.1 |

3600 |

22 |

|

LWS500 |

500 |

4.2 |

3000 |

30 |

|

LWS530 |

500 |

4.2 |

3000 |

30 |

|

LWS580 |

580 |

4.1 |

2800 |

45 |

|

LWS620 |

620 |

4 |

2800 |

45 |

|

Note: In case of differences between the table and the user manual, the latter shall prevail. |

||||